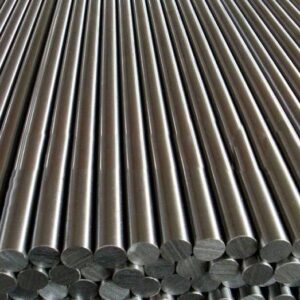

IS:2062 E165 Hot Rolled Bars / Black Bars - Delivery Conditions

| Section | Round |

| Size Range | Dia 6 mm to 65 mm |

| Condition | Hot Rolled |

| Tolerance offered | As per IS:2062 |

| Standard | Hot Rolled Bars to generally conform to IS:2062 |

| Straightness | As per IS:1852 where applicable |

| Ovality | Not specifically controlled, but within tolerance limits |

| Lengths offered | In full lengths up to 12000 mm / 40 ft. With prior agreement, fixed/custom lengths can also be offered. |

| Straightened | No, as rolled condition. |

| Polished | No |

| End Cut Condition | Generally supplied with as-rolled ends. Special end cuts or deburred ends can be offered upon request. |

| Colour Coding | Both ends are colour coded for easy identification. Buyer's colours can also be applied. |

| Rust Preventive | Hot Rolled Bars can be supplied with rust preventive coating upon request |

| Packing | Loose or Bundled with tie strings or wire and/or packed in chosen packing material |

| Test Report | Test Certificates for Chemical, Mechanical, and Physical properties as per agreement |

| Typical Mechanical Properties |

|

| Chemical Composition |

|

| Applications | IS:2062 E165 is widely used in structural applications, general engineering, and fabrication jobs such as making frames, beams, and other load-bearing components. |

| Melting & Refining Method | IS:2062 E165 is generally produced using Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF) methods, with secondary refining like Ladle Refining Furnace (LRF) to maintain consistent quality. |

| Rolling Route | The material is produced via the Continuous Casting route, where molten steel is cast into billets and then hot rolled into desired bar sizes. |

| Quality Control | Strict quality control processes are implemented, including chemical analysis, mechanical testing, and dimensional checks to ensure product quality. |

| Surface Condition | Hot Rolled Bars may have a scale-covered surface, which can be removed through pickling, shot blasting, or machining as per customer requirements. |

| Traceability | Each batch is fully traceable back to its heat number, ensuring documentation of all chemical and mechanical properties. |

- Indian Standard (IS): IS 2062 E165

- American (ASTM): ASTM A36, ASTM A1011 Grade 36, ASTM A283 Grade C, ASTM A500 Grade B

- European (EN): EN 10025 S235JR, EN 10025 S235J0, EN 10025-2 S185, EN 10219 S235JRH

- Japanese (JIS): JIS G3101 SS330, JIS G3101 SS400, JIS G3106 SM400A

- British (BS): BS 4360 Grade 40A, BS EN 10025 S235JR

- German (DIN): DIN 17100 St 37-2, DIN EN 10025 S235JR

- Korean (KS): KS D3503 SS330, KS D3515 SM400A

- Russian (GOST): GOST 380-2005 St0, GOST 27772 St3ps, GOST 19281 St3sp

- French (AFNOR): NF A35-501 E24-2, NF EN 10025 S235JR

- Italian (UNI): UNI 7070 Fe360B, UNI EN 10025 S235JR

- Canadian (CSA): CSA G40.21 260W

- Australian (AS/NZS): AS/NZS 3678 Grade 250, AS/NZS 1594 HA250

- Swedish (SS): SS 1411

- Chinese (GB): GB/T 700 Q235A, GB/T 700 Q235B

- South Korean (KS): KS D3515 SS330

- Turkish (TS): TS EN 10025 S235JR

- Brazilian (NBR): NBR 7007 A36, NBR 16271 S235JR

- South African (SABS): SABS 1431 Grade 250WA

- Mexican (NMX): NMX-B-506-C St 42

- Finnish (SFS): SFS 2357 Fe360B

- Spanish (UNE): UNE 36080 AE 235B

- Czech (ČSN): ČSN 41 1373 11 375

- ISO: ISO 630-2 S235JR, ISO 4950-1 Fe430B

- Argentinian (IRAM): IRAM IAS U500-259 Fe 360

- Polish (PN): PN EN 10025 S235JR

- Norwegian (NS): NS 143-83 B

- Romanian (STAS): STAS 500/2-80 OL 37-2

- Belgian (NBN): NBN EN 10025 S235JR

- Dutch (NEN): NEN 3850 S235JR

- Austrian (ÖNORM): ÖNORM EN 10025 S235JR

- Indonesian (SNI): SNI 07-2052

- Singapore (SS): SS S235JR

- Malaysian (MS): MS 1313 Grade 275

- Philippines (PNS): PNS 06-153 SS275

- Thai (TIS): TIS 1227 SS400

- Pakistani (PS): PS 1610 Grade 275

- UAE (UAE Standards): UAE.S. 380-2010 G250

- Vietnamese (TCVN): TCVN 1650-2008

- Hungarian (MSZ): MSZ EN 10025 S235JR

- Greek (ELOT): ELOT 361-102 Fe360B

- Bulgarian (BDS): BDS EN 10025 S235JR

- Swiss (SNV): SN EN 10025 S235JR

- Ukrainian (DSTU): DSTU EN 10025 S235JR

- Iranian (ISIRI): ISIRI 3766 Grade St37

- Egyptian (ES): ES 2031 Grade St37-2

- Saudi Arabian (SASO): SASO ASTM A36